圆振动筛概述

YA型圆振动筛运动轨迹为圆,可供选煤、选矿、建材、电力及化工等部门作物料分级用。筛机坚固耐用,振动噪音小,维修方便。

选用须知

- 筛机分单层和双层,并有轻型和重型之分。

- 筛网材质有编织网、冲孔筛板、聚胺酯筛网等。如果选用铁篦式筛板可按要求设计。

- 双层筛上层筛面选定的筛孔尺寸超过技术性能及参数中规定的筛孔尺寸时,按要求设计。

- 电动机可安装在左侧或右侧,无特殊要求按安装图表安装、供货。

- 给料箱为选择件,用户如有要求,可供给料箱。

- 在选用时如有改变筛面倾角的要求,可另行设计。

- 基础螺栓由用户自备。

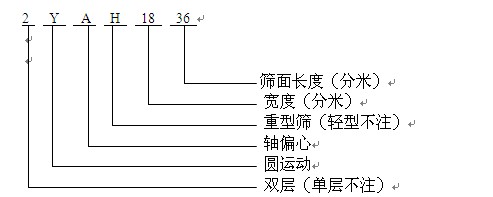

型号示例

技术参数

表一:

| 型号 | 筛 面 | 给料 | 处理量 | 振次 | 双振幅 | 电动机 | 外型尺寸 | 总重 | 每支点工作 | Zui大动负荷 | |||||||

| 粒度 | t/h | 次/分 | mm | 长×宽×高 | kg | 动负荷 | |||||||||||

| 层数 | 面积 | 倾角 | 筛孔尺寸 | 结 构 | mm | 型号 | 功率 | mm | 给料端 | 排料端 | 给料端 | 排料端 | |||||

| m2 | o | mm | kW | N | N | N | N | ||||||||||

| YA1236 | 1 | 4.3 | 20 | 6-50 | 编织 | ≤200 | 80-240 | 845 | 9.5 | Y160M-4 | 11 | 3757X2364X2456 | 4905 | ±802 | ±802 | ±4008 | ±4008 |

| 2YA1236 | 2 | 4.3 | 20 | 6-50 | 上 | ≤200 | 80-240 | 845 | 9.5 | Y160M-4 | 11 | 3757X2364X2456 | 5311 | ±802 | ±802 | ±4008 | ±4008 |

| 下编织 | |||||||||||||||||

| YA1530 | 1 | 4.5 | 20 | 6-50 | 编织 | ≤200 | 80-240 | 845 | 9.5 | Y160M-4 | 11 | 3184X2670X2280 | 4975 | ±843 | ±843 | ±4214 | ±4214 |

| YA1536 | 1 | 5.4 | 20 | 6-50 | 编织 | ≤200 | 100-350 | 845 | 9.5 | Y160M-4 | 11 | 3757X2670X2419 | 5137 | ±843 | ±843 | ±4165 | ±4165 |

| 2YA1536 | 2 | 5.4 | 20 | 6-50 | 上 | ≤200 | 100-350 | 845 | 9.5 | Y160L-4 | 15 | 3757X3715X2437 | 5624 | ±802 | ±802 | ±4008 | ±4008 |

| 下编织 | |||||||||||||||||

| YAH1536 | 1 | 5.4 | 20 | 30-150 | 冲孔 | ≤400 | 160-650 | 755 | 11 | Y160M-4 | 11 | 3757X2670X2437 | 5621 | ±931 | ±931 | ±4655 | ±4655 |

| 2YAH1536 | 2 | 5.4 | 20 | 30-200 | 上冲孔 | ≤400 | 160-650 | 755 | 11 | Y160L-4 | 15 | 3757X2715X2437 | 6045 | ±931 | ±931 | ±4655 | ±4655 |

| 6-50 | 下编织 | ||||||||||||||||

| YA1542 | 1 | 6.5 | 20 | 6-50 | 编织 | ≤200 | 110-385 | 845 | 9.5 | Y160M-4 | 11 | 4331X2670X2655 | 5515 | ±802 | ±802 | ±4008 | ±4008 |

| 2YA1542 | 2 | 6.5 | 20 | 30-150 | 上 | ≤200 | 110-385 | 845 | 9.5 | Y160L-4 | 15 | 4331X2715X2675 | 6098 | ±802 | ±802 | ±4008 | ±4008 |

| 下编织 | |||||||||||||||||

| YA1548 | 1 | 7.2 | 20 | 6-50 | 编织 | ≤200 | 120-420 | 845 | 9.5 | Y160L-4 | 15 | 4904X2715X2854 | 5918 | ±847 | ±847 | ±4234 | ±4234 |

| 2YA1548 | 2 | 7.2 | 20 | 6-50 | 上 | ≤200 | 120-420 | 845 | 9.5 | Y160L-4 | 15 | 4904X2715X2861 | 6321 | ±847 | ±847 | ±4234 | ±4234 |

| 下编织 | |||||||||||||||||

| YAH1548 | 1 | 7.2 | 20 | 30-150 | 冲孔 | ≤400 | 200-780 | 755 | 11 | Y160L-4 | 15 | 4904X2715X2943 | 6842 | ±1392 | ±1392 | ±6958 | ±6958 |

| 2YAH1548 | 2 | 7.2 | 20 | 30-150 | 上冲孔 | ≤400 | 200-780 | 755 | 11 | Y160L-4 | 15 | 4904X2715X2943 | 7910 | ±1392 | ±1392 | ±6958 | ±6958 |

| 下编织 | |||||||||||||||||

| YA1836 | 1 | 6.5 | 20 | 30-150 | 编织 | ≤200 | 140-220 | 845 | 9.5 | Y160M-4 | 11 | 3757X2975X2419 | 5205 | ±892 | ±892 | ±4460 | ±4460 |

| 2YA1836 | 2 | 6.5 | 20 | 30-150 | 上 | ≤200 | 140-220 | 845 | 9.5 | Y160L-4 | 15 | 3757X2975X2419 | 5946 | ±847 | ±847 | ±4234 | ±4234 |

| 下编织 | |||||||||||||||||

| YAH1836 | 1 | 6.5 | 20 | 30-150 | 冲孔 | ≤400 | 220-910 | 755 | 11 | Y160M-4 | 11 | 3757X2975X2437 | 5900 | ±980 | ±980 | ±4900 | ±4900 |

| 2YAH1836 | 2 | 6.5 | 20 | 30-150 | 上冲孔 | ≤400 | 220-900 | 755 | 11 | Y160L-4 | 15 | 3757X3020X2437 | 6350 | ±980 | ±980 | ±4900 | ±4900 |

| 6-50 | 下编织 | ||||||||||||||||

| YA1842 | 1 | 7.6 | 20 | 6-150 | 编织 | ≤200 | 140-490 | 845 | 9.5 | Y160L-4 | 15 | 4331X3020X2675 | 5829 | ±847 | ±847 | ±4234 | ±4234 |

| 2YA1842 | 2 | 7.6 | 20 | 6-150 | 上 | ≤200 | 140-490 | 845 | 9.5 | Y160L-4 | 15 | 4331X3020X2675 | 6437 | ±847 | ±847 | ±4234 | ±4234 |

| 下编织 | |||||||||||||||||

| YAH1842 | 1 | 7.6 | 20 | 30-150 | 冲孔 | ≤400 | 450-800 | 755 | 11 | Y160L-4 | 15 | 4331X3020X2700 | 6352 | ±928 | ±928 | ±4640 | ±4640 |

| 2YAH1842 | 2 | 7.6 | 20 | 30-150 | 上冲孔 | ≤400 | 450-800 | 755 | 11 | Y160L-4 | 15 | 4331X3020X2700 | 7037 | ±928 | ±928 | ±4640 | ±4640 |

| 下编织 | |||||||||||||||||

| YA1848 | 1 | 8.6 | 20 | 6-50 | 编织 | ≤200 | 150-525 | 845 | 9.5 | Y160L-4 | 15 | 4904X3020X2861 | 6289 | ±847 | ±847 | ±4234 | ±4234 |

处理量为参考值,以精煤的散密度为计算依据

续表一:

| 型号 | 筛面 | 给料 | 处理量 | 振次 | 双振幅 | 电动机 | 外型尺寸 | 总重 | 每支点工作 | Zui大动负荷 | |||||||

| 粒度 | t/h | 次/分 | mm | 长×宽×高 | kg | 动负荷 | |||||||||||

| 层数 | 面积 | 倾角 | 筛孔尺 | 结 构 | mm | 型号 | 功率 | mm | 给料端 | 排料端 | 给料端 | 排料端 | |||||

| m2 | o | 寸 | kW | N | N | N | N | ||||||||||

| mm | |||||||||||||||||

| 2YA1848 | 2 | 8.6 | 20 | 6-50 | 上 | ≤200 | 150-525 | 845 | 9.5 | Y160L-4 | 15 | 4904X3023X2861 | 6624 | ±847 | ±847 | ±4234 | ±4234 |

| 下编织 | |||||||||||||||||

| YAH1848 | 1 | 8.6 | 20 | 30-150 | 冲孔 | ≤400 | 250-1000 | 755 | 11 | Y160L-4 | 15 | 4940X3023X2943 | 7122 | ±1392 | ±1392 | ±6958 | ±6958 |

| 2YAH1848 | 2 | 8.6 | 20 | 30-150 | 上冲孔 | ≤400 | 250-1000 | 755 | 11 | Y160L-4 | 15 | 4904X3023X2943 | 7740 | ±1392 | ±1392 | ±6958 | ±6958 |

| 下编织 | |||||||||||||||||

| YA2148 | 1 | 10 | 20 | 6-50 | 编织 | ≤200 | 180-630 | 748 | 9.5 | Y180M-4 | 18.5 | 4945X3423X3515 | 9033 | ±1675 | ±1675 | ±8379 | ±8379 |

| 2YA2148 | 2 | 10 | 20 | 6-50 | 上 | ≤200 | 180-630 | 748 | 9.5 | Y180L-4 | 22 | 4945X3463X3515 | 10532 | ±1675 | ±1675 | ±8379 | ±8379 |

| 下编织 | |||||||||||||||||

| YAH2148 | 1 | 10 | 20 | 13-500 | 冲孔 | ≤400 | 270-1200 | 708 | 11 | Y180M-4 | 18.5 | 4945X3423X3501 | 10430 | ±2889 | ±2889 | ±14445 | ±14445 |

| 2YAH2148 | 2 | 10 | 20 | 30-150 | 上冲孔 | ≤400 | 270-1200 | 708 | 11 | Y180L-4 | 22 | 6092X3423X3674 | 11190 | ±2889 | ±2889 | ±14445 | ±14445 |

| 下编织 | |||||||||||||||||

| YA2160 | 1 | 12.6 | 20 | 3-80 | 编织 | ≤200 | 230-800 | 748 | 9.5 | Y180M-4 | 18.5 | 6092X3463X3674 | 9926 | ±2495 | ±2495 | ±12475 | ±12475 |

| 2YA2160 | 2 | 12.6 | 20 | 6-50 | 上 | ≤200 | 230-800 | 748 | 9.5 | Y180L-4 | 22 | 6116X3619X3849 | 11249 | ±2495 | ±2495 | ±12475 | ±12475 |

| 下编织 | |||||||||||||||||

| YAH2160 | 1 | 12.6 | 20 | 30-150 | 冲孔 | ≤400 | 350-1500 | 708 | 11 | Y200L-4 | 30 | 6116X3619X3849 | 12490 | ±2889 | ±2889 | ±14445 | ±14445 |

| 2YAH2160 | 2 | 12.6 | 20 | 30-150 | 上冲孔 | ≤400 | 350-1500 | 708 | 11 | Y200L-4 | 30 | 6116X3619X3849 | 14800 | ±2889 | ±2889 | ±14445 | ±14445 |

| 下编织 | |||||||||||||||||

| YA2448 | 1 | 11.5 | 20 | 6-50 | 编织 | ≤200 | 200-700 | 748 | 9.5 | Y180M-4 | 18.5 | 4945X3729X3473 | 9907 | ±2495 | ±2495 | ±12475 | ±12475 |

| YAH2448 | 1 | 11.5 | 20 | 6-50 | 冲孔 | ≤400 | 310-1300 | 708 | 11 | Y200L-4 | 30 | 4970X3925X3638 | 11830 | ±2889 | ±2889 | ±14445 | ±14445 |

| 2YAH2448 | 2 | 11.5 | 20 | 30-150 | 上冲孔 | ≤400 | 310-1300 | 708 | 11 | Y200L-4 | 30 | 4970X3925X3638 | 13012 | ±2889 | ±2889 | ±14445 | ±14445 |

| 下编织 | |||||||||||||||||

| YA2460 | 1 | 14.4 | 20 | 6-50 | 编织 | ≤200 | 260-780 | 748 | 9.5 | Y200L-4 | 30 | 6091X3925X3850 | 12240 | ±2495 | ±2495 | ±12475 | ±12475 |

| 2YA2460 | 2 | 14.4 | 20 | 6-50 | 上 | ≤200 | 260-780 | 748 | 9.5 | Y200L-4 | 30 | 6091X3925X3850 | 13583 | ±2495 | ±2495 | ±12475 | ±12475 |

| 下编织 | |||||||||||||||||

| YAH2460 | 1 | 14.4 | 20 | 30-150 | 冲孔 | ≤400 | 400-1700 | 708 | 11 | Y200L-4 | 30 | 6091X3925X3846 | 13096 | ±2889 | ±2889 | ±14445 | ±14445 |

| 2YAH2460 | 2 | 14.4 | 20 | 30-150 | 上冲孔 | ≤400 | 400-1700 | 708 | 11 | Y200L-4 | 30 | 6091X3925X3846 | 15100 | ±2889 | ±2899 | ±14445 | ±14445 |

| 下编织 | |||||||||||||||||

苏公网安备 32062102000295号

苏公网安备 32062102000295号